A valve is a device that controls, regulates, or directs the flow of a fluid, by closing, opening, or partially obstructing one or more passageways. Ball valves are a type of quarter turn valve that controls flow. They serve as more effective alternatives to similar valves, like butterfly valves and gate valves. Read More…

Marwin Valve is known for high quality products and customer service. Some products include ball valves, brass ball valves, high pressure valves, stainless steel ball valves, flanged ball valves, 4 way ball valves and 3 way ball valves. We serve a wide variety of industries. Please give us a call today to learn more information!

At Kingston Valves, we are proud to be recognized as a leading manufacturer and supplier of high-quality ball valves, catering to diverse industries worldwide with precision-engineered solutions that ensure efficient flow control and reliable performance. With decades of experience and a commitment to innovation, we have earned the trust of our customers as a dependable partner for all their...

When it comes to ball valves, you can count on Valve Check to manufacture ball valves and relief valves! Our valves can operate up to 10,000 PSI, and can be made from such materials as brass, aluminum, steel and stainless steel. Many standards and configurations available! For more information, call us today! We look forward to working with you!

Alloy Valves and Controls, Inc. (AVCO) manufactures valves and instrumentation devices for all types of fluid flow conditions. We supply standard and custom products with full control over our designs and manufacturing. We are proud to be an ISO 9001:2015 Certified, “Made in California” and “Women Owned” business. We produce control valves, cryogenic valves, sanitary valves and...

More Ball Valve Manufacturers

Note that ball valves are not the same thing as “ball check valves.” While the two have similar names, ball check valves are designed differently and serve a different purpose.

Applications

The goal of ball valves is to regulate fluid flow. They can do so in a number of ways. They can regulate some types of low flow valves, provide backflow prevention for valves with a swing check component, isolate systems, and provide gear operators with complete shut-off capabilities.

Because they are available with either manual or motorized controls, ball valves can provide their services to applications in a wide variety of settings.

Mostly, ball valves are used for on and off service of pipes containing suspended solids, slurries, liquids, or gases. Other applications that commonly employ ball valves include tubing systems, equipment, and tools in virtually every industry that transports fluids. You can find them anywhere from the factory floor to faucet at home. Industries that make use of ball valves include manufacturing, mining, oil and gas, agriculture, heating and cooling, plumbing industrial and domestic, water, consumer goods, construction and more.

History

The earliest example of something similar to the ball-type valve was the valve patented in 1871 by John Warren. His was a metal-seated valve that featured brass balls and brass seats. Warren ended up handing over the patent for his brass ball valve design to John Chapman, the head of Chapman Valves. For whatever reason, Chapman never put Warren’s design into production. Instead, he and other valve manufacturers used older designs for many years to follow.

The ball valve, also known as the spherical plug valve, finally came into play during World War II. During this time, engineers developed it for use in military aircraft fuel systems. After their success with ball valves in World War II, engineers adapted ball valves for industrial applications.

One of the most important ball valve-related breakthroughs of the 1950s was the development of Teflon and its subsequent use as a ball valve material. After the development of Teflon, a number of companies, such as DuPont, fought for the rights to its use, as they knew it would bring great market revenue. Eventually, more than one company were able to make Teflon valves. Teflon ball valves are flexible and can create a positive seal in two directions. In other words, they are bidirectional. They are also leak-proof. The first manufacturer to design ball valves with flexible Teflon seats was Howard Freeman, who patented his design in 1958.

Today, ball valves have evolved in a number of ways, including their material compatibilities and possible applications. In addition, they are able to use CNC machining and computer programming like the Button Model to make the best valves possible. Soon, ball valve manufacturers will be able to offer their products with even more options, including aluminum construction, less wear, and the widespread capability of throttling, which allows operators to pass variable amounts of fluid through a valve at a restricted flow.

Design

Materials

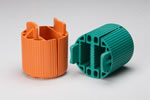

Ball valves may be made from materials including bronze, brass, titanium, ductile iron, cast iron, carbon steel, stainless steel, chrome, Teflon, PVC, and other plastics. Every material offers something different. For example, stainless steel ball valves are sure to be corrosion resistant and have a high tensile strength. PVC ball valves, on the other hand, gain all the positive qualities of this polymer, such as light weight and water, chemical, and concentrated acid resistant.

Considerations and Customization

When designing your ball valve, based on your application specifications, manufacturers decide on a number of design factors, such as ball material, valve body material, lining material, the ball valve dimensions, and the ball valve type. Details like this will determine how your ball valve reacts to environmental stressors like pressure, high and low temperatures (ball valves usually operate at room temperature), liquid flow, gas flow, vibration, impact, etc.

Ball valves are also available in a wide variety of custom sizes, from fractions of an inch, like miniature ball valves, to multiple yards in diameter. The smallest ball valves can control the flow of confined or hard-to-reach spaces. To find out about a manufacturer’s custom options, have a chat with a member of their sales staff.

Features

Ball valves feature a ball body, a ball, a port, seats, a stem, packing, a bonnet, and an actuator.

The body is a pressure vessel. It holds the flow control components, such as the ball. It is also the means by which operators can connect multiple pieces of tubing or pipe.

The ball is hollow, pivoting, and perforated.

The port is a hole that is bored through the middle of the valve.

Seats are round disks used to create a seal between the body and the ball.

The stem is a shaft. It helps the ball rotate by connecting it to the outside of the valve.

Packing consists of a number of flexible seals that are packed in around the shaft so that the valve does not leak.

The bonnet is a section of the body that contains the packing and the stem.

The actuator, sometimes called the operator, is a device such as a lever handle. The valve and actuator work together to rotate the valve stem. When the handle lies flat in alignment, the valve is open and when the handle sits at a perpendicular position, the valve is closed.

Types

Ball valves are chosen for an application based on their qualities. First, customers must choose between two primary design options: trunnion and floating ball.

Trunnion ball valves use additional mechanisms to anchor the ball to a certain spot, where they serve larger and higher-pressure valve applications. They are costlier than floating ball valves.

Floating ball valves, or float ball valves, use a non-anchored ball that drifts into place or floats slightly downstream into the seat, providing a tight seal.

Another consideration customers may take into account is whether the valve is motorized, actuated, or manual.

Motorized ball valves, per their name, use a motor to open and close itself.

Actuated ball valves operate with the help of an actuator that, while sitting on top of the valve, supplies force and motion. Using an actuator, the valve may be controlled either automatically or manually via a remote. The handle of trunnion ball valves, which rotates the ball at a one-quarter turn, may be any three of these.

Customers may also choose between a few other types of ball valves, such as flanged ball valves, multiport ball valves, non-return ball valves, and high-pressure ball valves.

Flanged ball valves feature outside edges that are raised into a flange, with holes placed in alignment with the piping system in which the valve will be placed. Flanged ball valves are valued for their simplicity and the ease with which they can be installed or removed from a piping system.

Multiport ball valves, such as 3-way and 4-way ball valves, have multiple ports through which flow passes. The way that the flow comes in an inlet and exits one or more outlets is controlled by both the handle rotation and the shape of the inlet port.

Three-way ball valves usually have T or L shaped ports.

Four-way ball valves usually have two L shaped ports.

Non-return valves, also called ball check valves, only direct fluid flow in one direction, though they do allow for both low and high pressure and temperature flows.

High pressure ball valves are those ball valves that are able to control both high and low flow applications with high temperature and pressure ratings, up to around 7500 psi.

Globe valves are an advanced type of ball valve designed to regulate flow. Often, manufacturers install them in automobiles, where they act as transmission control valves. They are named after their shape. They are disc-like and look like valve globes.

Advantages

Ball valves are popular for a number of reasons. First, they are popular for the fact that they have a variety of material options. Second, ball valves are popular for the fact that they are easy to clean. Ball valves are largely self-cleaning because, as the ball of a ball valve rotates, the seat wipes itself, effectively preventing any buildup. In addition, because they have no internal components, they require little maintenance and they do not retain internal debris. Instead, they are highly controlled and they are blowout proof. Likewise, they are easy to monitor. Next, ball valves are very diverse and customers can use them for a wide range of applications. Finally, ball valves are cost-effective and reliable.

Accessories

Accessories for ball valves are essential components that enhance their functionality, convenience, and safety in various applications. One commonly used accessory is the handle or lever, which allows manual operation of the valve, enabling users to easily open or close the valve by rotating it. Another important accessory is the actuator, which provides automated control of the ball valve. Actuators can be pneumatic, electric, or hydraulic, and they enable remote operation and precise control of valve position, making them ideal for applications where frequent valve operation is required. Additionally, there are various mounting brackets and couplers available to facilitate the installation and connection of ball valves in different systems. Other accessories include position indicators or limit switches that provide visual or electronic feedback on the valve’s position, helping to monitor and control the flow. Furthermore, stem extensions are utilized to extend the length of the valve stem, allowing for easier accessibility in hard-to-reach locations. Finally, protective enclosures or covers can be used to shield ball valves from harsh environments, preventing damage and ensuring their long-term reliability. Overall, these accessories contribute to the versatility, efficiency, and safety of ball valves in a wide range of industrial, commercial, and residential applications.

When purchasing accessories for ball valves, it is important to consider a few key factors to ensure compatibility and optimal performance. One should begin by checking with the supplier or manufacturer of the ball valve itself. Suppliers often offer a comprehensive range of accessories specifically designed to work seamlessly with their ball valves. Consulting the supplier allows you to access their expertise and guidance in selecting the appropriate accessory for your specific valve model and application requirements. They can provide valuable information on factors such as compatibility, installation guidelines, and any additional considerations that may be necessary. By involving the supplier in the purchasing process, you can mitigate the risk of choosing an accessory that may not fit or function properly with your ball valve. Additionally, the supplier may have valuable insights on the latest accessories available in the market and any technological advancements that could benefit your application. Ultimately, checking with the supplier before purchasing any accessory for ball valves ensures that you make an informed decision and obtain the right accessory that will enhance the performance and longevity of your ball valve system.

Proper Care

Proper care and maintenance of ball valves are crucial to ensure their longevity, reliable performance, and to prevent potential issues.To start, regular inspection is important to identify any signs of wear, leakage, or damage; a general recommendation is to perform visual inspections at least once every six months or as specified by the manufacturer. Check for leaks around the valve body, stem, and connections. Lubrication is another essential aspect of maintenance. Apply a suitable lubricant to the valve stem and seals as recommended by the manufacturer. This helps to reduce friction, prevent corrosion, and ensure smooth operation. Additionally,to prevent debris from building up, ball valves should be exercised by fully opening and closing them at least once every three to six months or as indicated by the manufacturer’s guidelines. If the valve is installed in an environment with harsh conditions or corrosive substances, it may also be necessary to implement additional protective measures such as coatings or corrosion-resistant materials. Finally, following the manufacturer’s guidelines for any specific care or maintenance procedures is highly recommended, as they can provide valuable insights on the unique requirements of the ball valve and its accessories. By adhering to these practices, one can effectively care for ball valves and extend their lifespan while maximizing their performance and reliability.

Standards

Various standards have been established for ball valves to ensure uniformity, quality, and safety in their design, manufacturing, and use. These standards, such as those set by organizations like the American Petroleum Institute (API), International Organization for Standardization (ISO), and the American Society of Mechanical Engineers (ASME), provide guidelines and specifications that manufacturers and consumers should adhere to. Following these standards is crucial for consumers as they promote consistency and compatibility, allowing for interchangeability of components and ease of integration within systems. Standards also address important aspects like pressure ratings, materials, dimensions, testing procedures, and performance criteria, ensuring that ball valves meet the necessary requirements for specific applications. Compliance with these standards helps to enhance reliability, prevent failures, and ensure the safety of personnel and equipment. Furthermore, by adhering to established standards, consumers can have confidence in the quality and performance of the ball valves they purchase, facilitating informed decision-making and reducing potential risks associated with substandard products. Ultimately, adherence to ball valve standards promotes industry-wide best practices and harmonization, benefiting both manufacturers and consumers in terms of efficiency, safety, and reliability.

Choosing the Right Ball Valve Supplier

To ensure the most beneficial outcome when purchasing ball valves from a ball valve supplier, it is important to compare several businesses using our directory of ball valve suppliers. There, each ball valve supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each ball valve business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple ball valve companies with the same form

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services